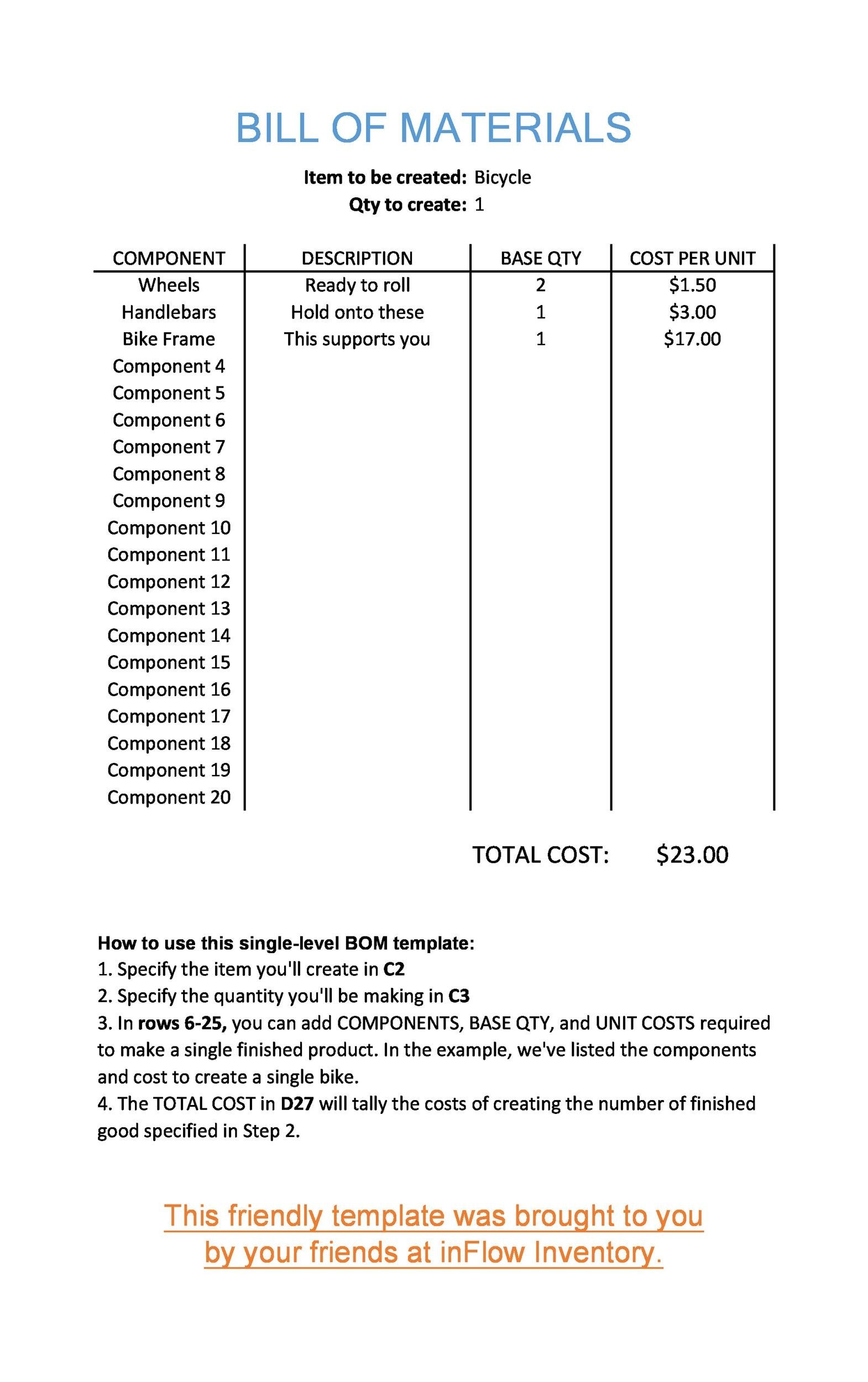

The most important part is that with your bill of materials, you constantly serve the next stage in your production process. This is very dependent on the amount of modularity within your product range. Now that you know why creating a good BoM is essential, you naturally want to know how to actually create one. BoM creation: How do you create a good bill of materials? But it’s very important that the two are working seamlessly together, but also apart. There’s a difference between a sales bom and a production bom. On top of that a good BoM process creates clarity for the customer and ensures an exact translation of the customer’s wishes for production. Less frustration will occur and management will be able to make better informed choices.

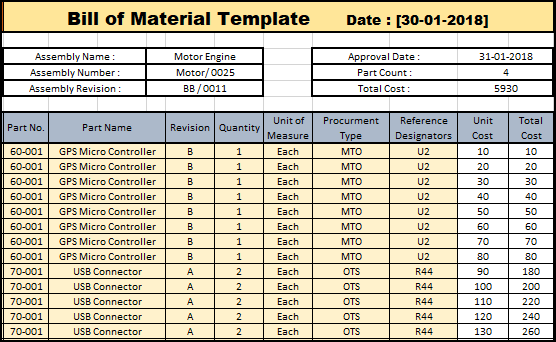

The same principle counts for electronic components and associated software. And even for this coating a separate bill of materials may be needed. Further adjustments of parts will also be present on the BoM, for instance when a piece of steel should- or should not have coating. When a part needs to be created, an underlying BoM will be necessary to determine the materials required to make this part. This means physical items that have to be produced or bought. And when we say all of them, we mean all of them. When talking about BoMs, we mean an overview of all required parts and materials to realize a customer’s configuration. Back to the basics: what is a BoM for manufacturing (Bill of Material)? Good to know in advance is that they are often referred to with the abbreviation BoM. In this blog you will read all you need to know about bills of materials for the manufacturing industry. To deliver high quality, your bills of materials should be of high quality as well.

And then there is the exact configuration a customer has chosen, which you will have to measure up to. More often than not you will have to deal with coherence between moving parts, electronics, and software. Often in this industry you will deal with more complex things than a couch or other furniture, and iwn turn the bill of materials will be much more complex. You have Bills of Materials (BOM), and then you have Bills of Materials for the manufacturing industry.

0 kommentar(er)

0 kommentar(er)